- Porsche is advancing EV sustainability by recycling old batteries into ‘black mass,’ a material rich in vital elements like lithium, nickel, cobalt, and manganese.

- The process involves breaking down retired batteries to extract valuable materials for creating new power cells, achieving significant recycling milestones with 65 tons of black mass collected so far.

- The company aims to achieve independence from volatile raw material markets and meet EU’s recycling mandate of an 80% lithium recovery by 2031.

- With only 5% of EV batteries currently recycled, Porsche’s initiative underscores the potential and urgency for more sustainable practices in the automotive industry.

- Porsche challenges the industry to rethink energy lifecycles, turning waste into value, and harmonizing technology with ecology for a greener future.

Amidst the whir of machinery and the silent call of sustainability, Porsche crafts a tale of reinvention—one in which the heart of an electric vehicle (EV) lives anew. The German automaker is forging a bold path into the future, one driven by the ‘black mass,’ a mysterious composite born from the guts of retired high-voltage batteries, ripe with promise and potential.

Inside Porsche’s expansive facility, the air hums with aspiration as colossal machines devour used EV batteries, reducing them to fragments and pressing them into what scientists call ‘black mass.’ This inky mixture conceals a treasure trove—lithium, nickel, cobalt, manganese—each element vital to the next generation of power cells, each bite from yesterday’s battery offering a taste of tomorrow’s drive.

Imagination gives way to meticulous separation as these coveted materials are teased apart, one by one. The grains of black mass yield their secrets, releasing components of purity fit to be reborn into the very soul of new electric Porsches. Thus far, Porsche has amassed 65 tons of this dense bounty—a testament to its resolve.

This endeavor tiptoes around the volatile dance of geopolitics that often governs raw material markets, aiming instead for independence. Should Porsche succeed, its method could ripple across the industry, illuminating a sustainable way forward. The company navigates a maze of European Union mandates, where edicts command an 80% recycling recovery target for lithium by 2031.

Yet, beyond regulatory frameworks and economic prudence lies a stark revelation: while 95% of the materials within a lithium-ion battery are recoverable, a mere fraction—only 5%—of EV batteries find their way back into the cycle of use. Porsche’s quest is not just a bid for better batteries but a call to honor our finite Earth by breathing new life into what is often discarded.

Through this recycling experiment, Porsche extends an invitation—a challenge—to the automotive world: To rethink the lifecycle of energy, to find value where others see waste, and to pave a path where technology and ecology coalesce. As engines rev and wheels turn, Porsche whispers a vision where sustainability drives, innovation steers, and the road unfurls a little greener.

Porsche’s Sustainable Battery Revolution: Unlocking the Future of EVs

Introduction

In the automotive world, Porsche has embarked on an ambitious project: transforming used electric vehicle (EV) batteries into a resource for the future. This initiative not only highlights the brand’s commitment to sustainability but also presents a model that could redefine battery recycling globally.

What is ‘Black Mass’?

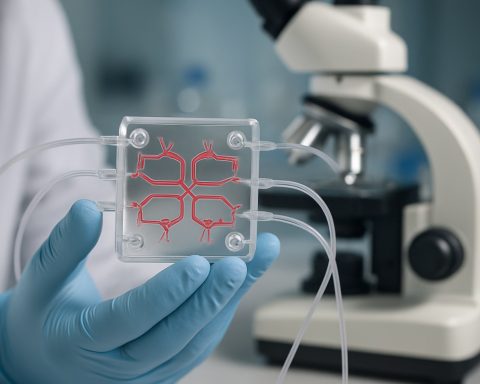

At the core of Porsche’s innovation is ‘black mass,’ a complex material created from the remnants of used lithium-ion batteries. This substance is crucial as it contains valuable materials like lithium, nickel, cobalt, and manganese—ingredients vital for manufacturing new EV batteries.

How Porsche is Redefining Recycling

1. Collection and Disassembly: Porsche collects and breaks down retired EV batteries, crushing them into a fine powder to form ‘black mass.’

2. Material Separation: Advanced pyro-metallurgical processes then extract individual materials from the black mass, with precision that allows the recovery of nearly pure components.

3. Reintegration: These materials are reintegrated into the production cycle, providing raw materials for new batteries without the need for new mining operations, thus reducing environmental impact.

Challenges and Opportunities

1. Geopolitical Independence: By recycling materials internally, Porsche decreases reliance on global raw material markets, which are subject to geopolitical instability.

2. Regulatory Compliance: The European Union mandates an 80% recovery target for lithium by 2031, a goal Porsche’s methods are well-aligned with, potentially setting a new industry standard.

Real-World Use Cases

– Sustainability Leadership: Porsche’s approach could inspire other automakers to innovate towards sustainability, minimizing the industry’s environmental footprint.

– Cost Efficiency: Recycling can potentially reduce costs associated with new material procurement, leading to more affordable EVs.

Industry Trends and Predictions

– Increased EV Adoption: As recycling technology improves, more automakers may adopt similar practices, hastening the world’s transition to electric vehicles.

– Battery Recycling Market Growth: The battery recycling market is projected to grow significantly, with increasing attention from automotive and tech sectors advancing this trend.

Controversies and Limitations

– Technological Complexity: Implementing such an intricate recycling process requires significant upfront investment and technological expertise.

– Current Low Recycling Rates: Despite the efforts, only 5% of retired EV batteries currently re-enter the recycling stream, necessitating broader adoption of systems like Porsche’s.

Conclusion

Porsche’s work with ‘black mass’ is a clarion call for a sustainable and innovative future. To capitalize on this potential, stakeholders across industries should focus on enhancing recycling infrastructures and encouraging regulations that support such advanced recycling efforts.

Actionable Recommendations

– For Automakers: Invest in sustainable technologies and partner with recycling experts to reduce the environmental impact of EV production.

– For Consumers: Support brands that prioritize sustainability and inquire about the lifecycle management of their EV batteries.

– For Policymakers: Encourage regulations that incentivize recycling and penalize waste, boosting the shift towards a circular economy in the automotive sector.

For more insights into sustainable automotive innovations, visit the official Porsche website.